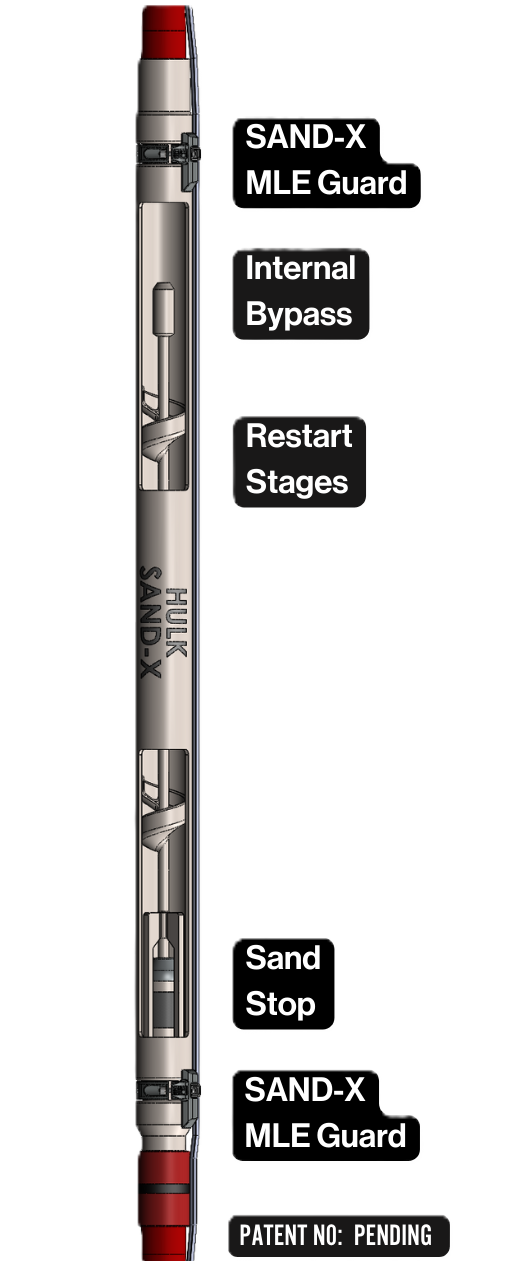

HULK SAND-X PDV: Stop Producing Sand Twice!

Patented SAND-X PDV delivers all the benefits of SAND-X with the added feature of allowing pump down treatments of 2+ BPM. Patent: Pending

SAND-X PDV FACTS

Patent: PENDING

100% Stainless 13Chrome

Factory Acceptance Tested to 5000 psi

Anti-Collapse Design

Supports Pump Down Treatments to 2+ BPM

Flow Rates up to 6,000 BPD

Temperature rating 400°F

SAND-X PDV Advantages

Prevents Sand Fallback on ESP During All Phases of Shutdown

Equalization (Industries Only Engineered Solution)

Fallback (Snow Globe Effect)

Eliminates Sand Pack-off Related Challenges and Failures

Delivers Smooth ESP Restarts in seconds

Internal Bypass Enables Pumping from Surface Down Tubing

2+ Barrels Per Minute

Well Control, Acid, and Chemical Treatments

SAND-X PDV Key Performance Indicators

sand-x pdv FAQs

-

99% efficiency separating 100-mesh sand during our latest pressure testing

-

Everything is 100% 13Chrome (high strength SS). Double O-ring design on top and bottom of housing mimics ESP best-practices

-

SAND-X PDV will help clear gas for restarts

-

65 cups of sand

-

Two separate Lab and Field Tested Patents on SAND-X PDV:

The Restart Stages on the shaft break up sand in the chamber during restart. When the tool fills up with a column of sand, the Restart Stages break up the bridge and allows the tool to flush completely in three seconds.

Sand Stop prevents sand from passing into the ESP during Equalization and Fallback. Sand Stop is a bypass for fluid.

-

Yes, SAND-X PDV features an internal bypass that enables pumping from surface at 2+ BPM

-

Yes:

At 6000 BPD, the back pressure of SAND-X is 50 psi

At 4000 BPD, the back pressure of SAND-X is 35 psi

Tested up to 13000 BPD